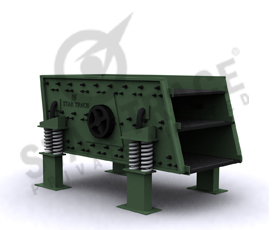

Vibrating Equipments- Vibro Screens

Star Trace actively catering to the needs of various industries as the single source, for custom Built Material Handling systems and equipments, have added over the years to the manufacturing program, a wide range of size reduction and separation equipments.

Star Trace updated know-how, product development, research and awareness is making crushing and screeing jobs more efficient. In addition to the various types of crusher and vibrating screens, Star Trace takesup turnkey jobs of complete crushing and screenng plants, right from concept to commissioning, capable to handle all kinds of rocks, ores, mineral and lumpy hard materials, even, quarries and other industries.

Star Trace Vibrating Screens has wider range of applications. It is a two bearing free floating vibrating screen which efficiently screens all moderately free flowing materials. The circular throw action is dervied from unbalance weights which are suspended from the vibrator unit and transmit an uniform vibration to screening surface and ensures that material travels over the screening surface at a constant rate. The amplitude of degree of vibration can be adjusted to suit charge of duty by adding or removing unbalance weight plates. Circulars motion ensures rapid stratification at the feed end separates sized product in the shortest possible time.

Screen's inclination normally varies between 15 Deg. and 20 Deg. and can can be installed with fixed angle or adjustable bracked arrangement. Speed of screen varies between 800 R.P.M and 1200 R.P.M Screens are manufactured in following widths 600, 800, 1000.1200, 1400, 1600, 1800, 2000 m.m and and lengths varying from 1200 mm to 600 mm Number of decks can be upto four.